Through extensive hydraulic fluid analysis Helgesen has developed multiple patented technologies to meet increasing market demand in hydraulic efficiency and performance becoming the global leader in. Hydraulic oil spends most of its time in the reservoir and as such various tank design criteria provide benefits for the hydraulic system as a whole.

Part 2 Reservoir Hydraulic Power Pack Basic Hydraulic Pneumatic Hindi English Youtube

A good hydraulic reservoir should have internal baffles situated in such a way that they prevent return line air from being drawn into the pump inlet.

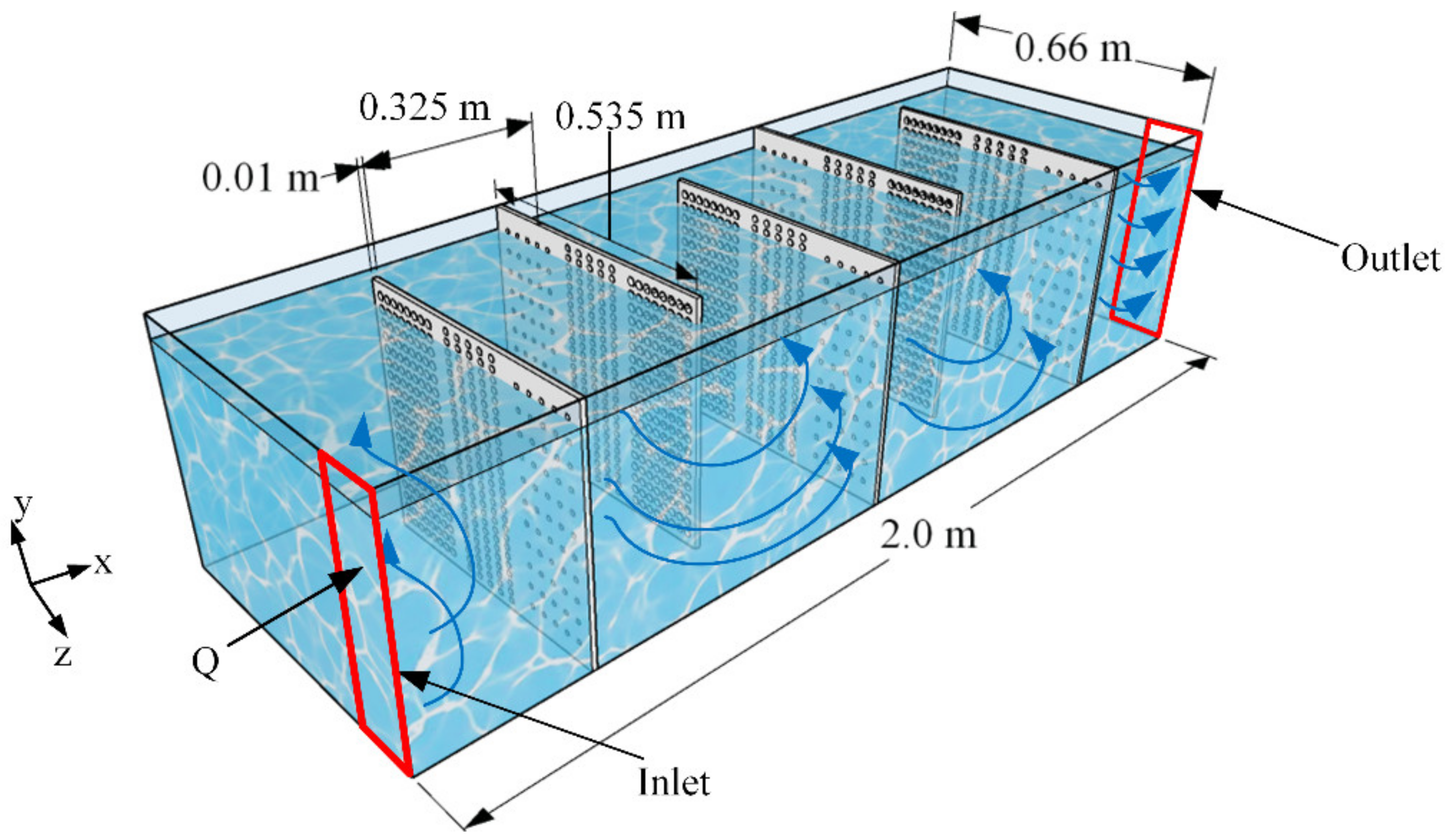

. Standard baffle configuration utilises 3 or 4 equally spaced vertical baffles T12 where T is the internal tank diameter. The contribution of jets emerging from the perforations to the mixing process is evaluated in terms of standard mixing indexes for various perforation parameters such as the solidity ratio and hole diameter. Hydraulic tank design is often neglected part of the development.

On the one hand a small oil volume results in lower total cost of ownership which gets more. In the context of the design of a hydraulic tank there are different incentives to design the oil tank as small as possible. Suitable for vertical mounting of pump electric motor.

When designing the optimum hydraulic reservoir most of the considerations are in keeping the oil clean and cool. Hydraulic Tank Baffle Design. Company standard which has been around for years states that oil passage cutouts have an area at least 2-12 times the total pump inlet area.

A hydraulic liquid reservoir includes a tank that has a plurality of walls and a baffle structure which divides the inside of the tank into three compartments. The article provides a concise account of the constructional details of hydraulic reservoirs. Request PDF Hydraulic design of baffles in disinfection contact tanks This study focuses on understanding the hydraulic design of baffled contact tanks using computational fluid.

A complete range of 36 textbooks in Paperback Kindle eBooks Editions on Pneumatics and Hydraulics under Fluid Power Educational Series authored by Joji Parambath has. The standard baffle design parameters are as follows. Hydraulic Reservoir System Design.

Fluid disturbances are commonly called sloshing and cause a number of issues such as breather damage short-circuiting diffusion and entrainment. The paper presents the development of industrial 400 litre hydraulic tank. Two rectangular contact tanks were used both of which are assumed to be representative of disinfection tanks for small municipalities throughout the.

Finished with power coating inside andout Lids. Never rework a fuel tank into a hydraulic tank. An inlet is connected to one lower compartment while an outlet is connected to the second lower compartment and a third upper compartment is interconnected with both the first and second lower compartments at a.

Baffles and inlets are assessed in depth using both physical tracer studies and computational fluid dynamics CFD simulations. Locate the inlet tube under a substantial depth of oil to avoid vortexes or add vanes to the throat of the tube extending outward. Increasing the size or number of baffles beyond this point does little to increase the effectiveness of the mixing.

The reservoir should have internal baffles to reduce sloshing and to prevent the hot returning oil from immediately entering the pumps intake port. A physical barrier baffle that separates fluid entering the reservoir from fluid entering the pump suction line air space above the fluid to accept air that bubbles out of the fluid access to remove used fluid and contaminants from the system and to add new fluid. Hydraulic Oil Tanks 10L to 400L Brand.

Power response and flow response is always carried out in a vessel that has four standard width baffles width 112th of the tank diameter. Furthermore large scale turbulent eddies shed by the perforations contribute to the mixing process in the chambers of the tank. Baffles work to efficiently separate the return flow from the inlet flow.

Reservoirs in industrial applications are spoiled by the extra. H L S 15S 15 SUpper baffle Lower baffle Minimum water level Port from previous channel Exit to the sedimentation tank entrance channel. If G is too great shear forces will prevent the formation of large floc If G is insufficient adequate collision will not occur.

Finished in black steel only Painted Tanks. Steel welded inside outside Unpainted Tanks. Hydraulic oil in mobile equipment reservoirs has disturbances caused by the motion of the equipment.

Hydraulic tank baffle design From highlighters to doughnuts unicorn almost everything is arguably one among the largest millennial trendsSo why must you deprive your nails of the mystical makeover. Baffles direct diffuse and contain fluid and increase tank stiffness Fig. 5 t 1030 min contact opputinity in the basin small l arg e floc t 10 30 min small l arg e floc G light dense floc Gt 10 5 contact opputinity in the basin 10 -75 sec -1 10.

Such designed solutions are baffles. To help cool return fluid it should be. H Water depth L Length of the flocculator channel S Space between baffles T Thickness of the baffles B Perpendicular center to center distance between baffles.

In this article sloshing is illustrated. The default number of baffles is four 4. With the use of the perforated baffle design it is shown that the hydraulic efficiency of the tank can be improved from average to superior according to the baffling factor and the associated mixing in the proposed design can be.

October 20 2014 By Josh Cosford. As you are aware a hydraulic reservoir is an essential part of a hydraulic power pack. This allows more heat to radiate as it takes a longer route in the tank.

In order to reduce oil swirling and improve stability of fluid flow CFD simulations of oil flow inside hydraulic tank were made. Additionally baffles help the reservoir fluid circulate which promotes heat dissipation from the fluid. Turbulent flow through the perforated baffle is studied at the perforation hole scale.

Looking for rules of thumb on baffle design for hydraulic tanks. 10 Things To Know Before Buying A. Mobile Equipment Reservoir Baffle Innovation.

10 Things To Know Before Buying A Fuel Tank. Supplied upainted unless painting is specified larger tanks are fitted with a centre baffle. In this study a perforated baffle design is proposed to improve mixing in contact tanks.

The maximum hydraulic force in pounds acting on each baffle can be calculated from the transmitted torque divided by one half the distance between the baffles edges and by the number of baffles. How do I calculate the required thickness and supports for anti-swirl tank baffles. Number of Baffles and Baffle Width.

Do that standout glitter design with a. 7 Solid Reasons Why You Would Choose Propower As Your Tank Supplier. Hydraulic System Design Operation.

Hydraulic Tank Baffle Design. Several variations of new hydraulic tank designs are compared. Diesel Tanks D-Tank Hydraulic System Design and Operation Hydraulic Reservoir Guide Hydraulic Reservoir Tank Industry Connections Further Reading.

Why The Tank May Well Be A Hydraulic Fluid S Best Friend

Novel Slot Baffle Design To Improve Mixing Efficiency And Reduce Cost Of Disinfection In Drinking Water Treatment Journal Of Environmental Engineering Vol 143 No 9

Industrial Hydraulics Design Hydraulic Reservoir Design

Water Free Full Text A Perforated Baffle Design To Improve Mixing In Contact Tanks

Hydraulic Tank Design And Work Basic Stuffworking Com

Hydraulic Tank Design And Work Basic Stuffworking Com

0 comments

Post a Comment